Take your business efficiency to new heights with our Power Motion 𝑖-A Plus, designed specifically for the motion control market. This versatile motion controller is designed for complex multi-axis applications. It supports a wide range of synchronous functions and can be seamlessly integrated with FANUC robots. This integration enables efficient and precise control of robot motions, making it ideal for a wide range of industrial applications.

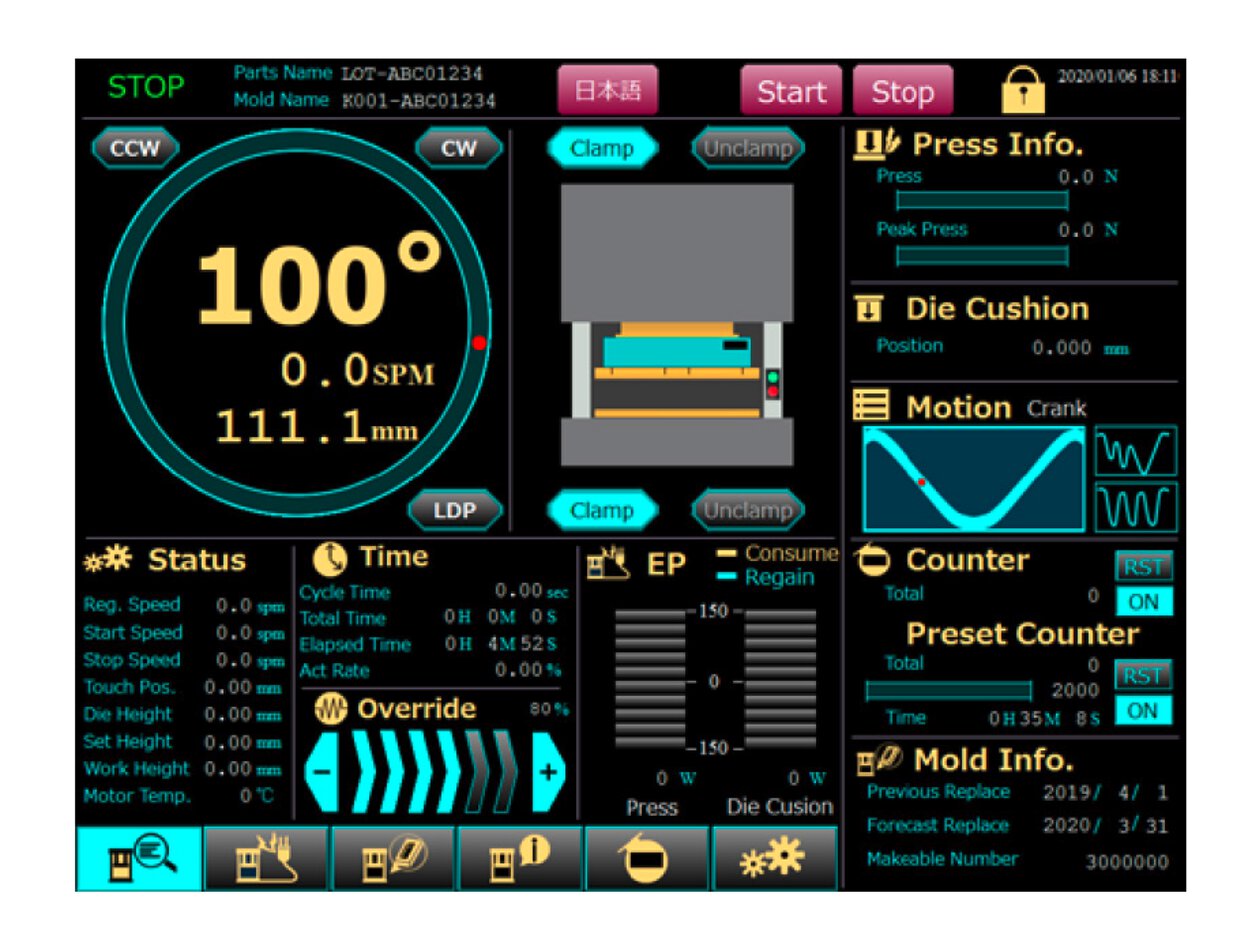

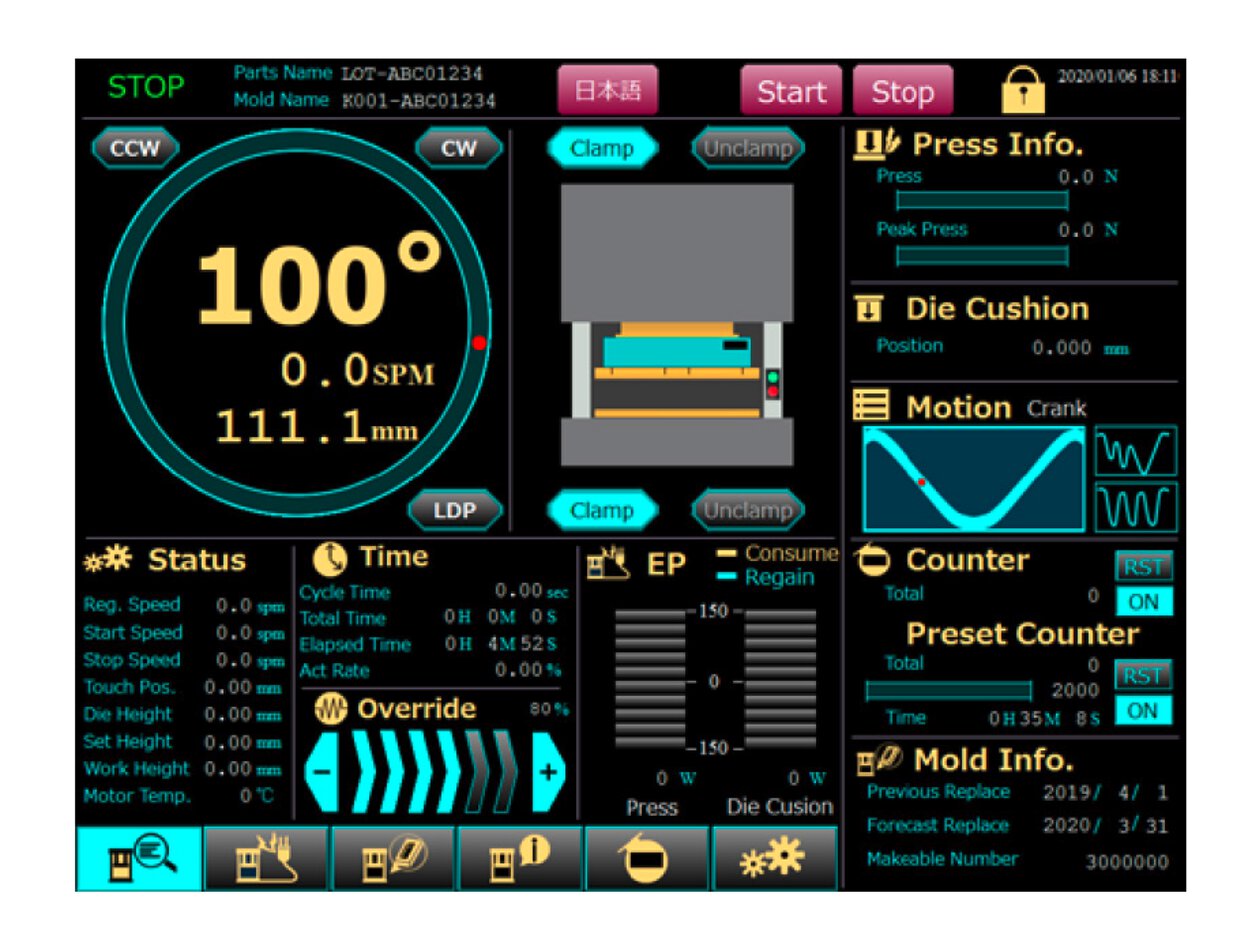

(Screen Customisation — FANUC PICTURE 2)

| Max. controlled axes total / per path |

32 / 24 |

| Max. spindle axes total / per path |

6 / 4 |

| Max. controlled paths |

10 |

Highlights

Benefits for Your Business

|

|

|

| Enhanced Precision and Control |

Complete Plug + Play Solution |

Scalability and Flexibility |

| This system delivers unmatched precision and control for intricate industrial tasks. Advanced algorithms and hardware boost machinery accuracy, minimise waste, and enhance product quality. |

Power Motion 𝑖-MODEL A Plus offers user-friendly, plug-and-play technology with included software and connects to machines with minimal wiring. |

Power Motion 𝑖-MODEL A Plus provides precision and efficient control for diverse industrial applications. |

Specifications

Technical Data

| Axis control |

| Max. controlled axes total / per path |

32 / 24 |

| Max. feed axes total / per path |

32 / 24 |

| Max. spindle axes total / per path |

6 / 4 |

| Max. simultaneously controlled axes per path |

4 |

| Max. controlled paths |

10 |

| Type of installation |

| LCD version |

Yes |

| Stand-alone version |

Yes |

| Operating Units |

| LCD panel |

Yes |

| LCD panel for iHMI |

Yes |

| PC front-end |

Yes |

| PC front-end iHMI |

Yes |

| Touch systems |

Yes |

| Handheld control unit |

Yes |

| Machine operators panel |

Yes |

| PMC Functions |

| Max. number of I/O |

4096 |

| Max. number of I/O-Link |

2 |

| Max. number of PMC channels |

5 |

| Maximum steps |

300000 |

| Block function |

Yes |

| CNC functions |

| Dual Check Safety |

Yes |

| Smart Machine Control |

Yes |

| Nano Interpolation |

Yes |

| AI Advanced Preview |

Yes |

| AI Contour Control |

Yes |

| Macro Executor |

Yes |

| C-Executor |

Yes |

| FANUC Picture |

Yes |

| FOCAS |

Yes |

| 5-axis function |

| – Tilted Working Plane |

No |

| – Tool Center Point Control |

No |

| – Smooth simultaneous 5-axis machining |

No |

| Error compensation |

| – Error Compensation |

Yes |

| Tool functions |

| – Tool Functions |

Yes |

| Technologies |

| General automation |

Yes |