Minimum tolerances of a few μm and top surface quality: You can meet these requirements with the versatile machining centers of the 08 Series. All models stand for high performance in a compact form. They are quick to set up, easy to operate, very stable, highly dynamic, and low-maintenance. Their modular design makes it possible to configure each basic machine to an individual solution that is perfectly tailored to your manufacturing needs.

08 Series machining centers are available with a single or double spindle, for 5-axis simultaneous machining, with workpiece changing during machine operation for large quantities, and as a mill-turning machine for multi-functional machining from the bar. In addition, the precision+ designation includes all machine types with linear direct drive as further variants for the special requirements of medical and precision technology.

Highlights

- Reliably strong performance

- Compact machine layout

- Vertical moving column principle

- Steel/mineral-cast machine bed

- High rigidity and thermal stability

- Motor spindles with water cooling

- Dynamic direct drives and precision guides with Precision+

- Fully enclosed working area, stainless steel covers

- Ideal chip flow

- Ergonomic operating and loading concept

- Easy access to all units for servicing

- Easily expandable with tailor-made automation

Technical data

| Max. Travel X – Y – Z |

450 – 270 – 360 mm |

| Max. spindle power |

18 kW |

| Max. spindle speed |

54’000 rpm |

| Max. axis acceleration |

1,3 g |

| Max. rapid feed speed |

100 m/min |

| Approx. chip-to-chip time |

2,5 s |

| Max. number of tools |

96 |

| Tool taper |

HSK-A32 / HSK-E32 / HSK-A40 / HSK-E40 |

| *Specific parameters are dependent on the machine’s model |

Example applications

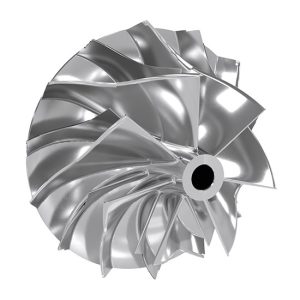

Automotive

-

-

Aluminium, Impeller

-

-

Aluminium, cast, Scroll

Medical technology

-

-

Titanium, Fragment plate for spinal column

-

-

Polyethylene, Knee inlay

-

-

Titanium, Bone plate

-

-

Titanium, Finger plate

-

-

Titanium, Spinal distractor

-

-

Stainless steel, Angle piece, dental drill

-

-

Titanium, Spinal distractor

-

-

Stainless steel, Endoscopy component

-

-

Titanium, Abutment

-

-

Stainless steel, Scissor parts

-

-

Titanium, Shoulder implant

-

-

Plastic, Aligner

Precision technology

-

-

Brass, Watch plate

-

-

Golden ring

-

-

Stainless steel, gold, ceramic, Watch bezels

-

-

Stainless steel, gold, ceramic, Watch case

-

-

Golden pendant

-

-

Stainless steel, gold, Bracelet clasp

-

-

Stainless steel, Bracelet link

Mechanical engineering

-

-

Stainless steel, Nozzle body holder

-

-

Stainless steel, Valve housing

-

-

Piston, Steel