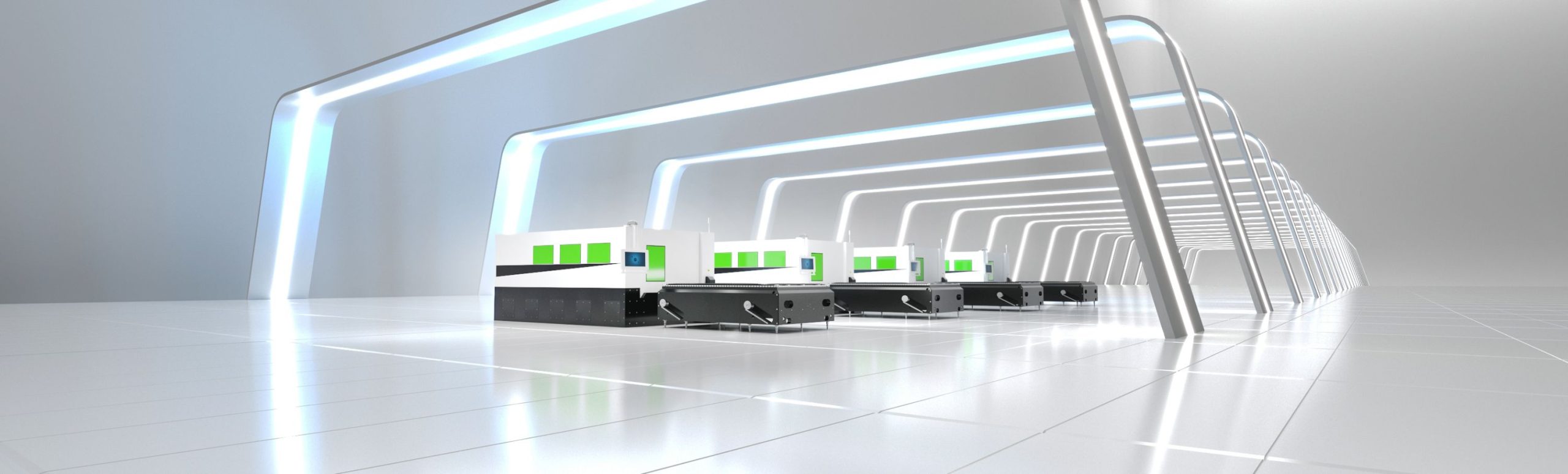

The eSmart series cutters are the epitome of economy – they don’t take up a lot of room, and they are easy to use and attractive in price. eSmart can handle short and long series as well as single piece cutting. With a cutting speed of up to 100 m/min, acceleration up to 2G and a laser fiber of 1 to 10 kW, eSmart provides efficient work with an excellent price/performance ratio.

The simple design makes constant supervision of the process possible thanks to the positioning of the pallet changer at the operator side. The eSmart series makes it easy to produce short batches from incomplete sheets, making it the optimum solution for small production facilities and for processing materials for your own requirements.

The reliability and performance of the eSmart laser cutters is based on top quality components. Thanks to being equipped with a laser source fiber, the eVa cutting head and a modern body, the machines significantly reduce the cost of cut parts. The fact that the eSmart laser cutting machines have the best components and an attractive price makes them the most frequently used machines for manufacturing a company’s internal requirements.

Eagle cutters are designed to meet the highest customer expectations. The standard version provides exceptionally high work efficiency, full process automation and low production costs.

| Machine model | […] | 1530 | 2040 |

|---|---|---|---|

| X-axis | [mm] | 3060 | 4070 |

| Y-axis | [mm] | 1540 | 2098 |

| Z-axis | [mm] | 100 | 100 |

| Max. sheet weight | [kg] | 1000 | 3200 |

| Machine model | […] | 1530 | 2040 |

|---|---|---|---|

| Length | [mm] | 10000 | 11570 |

| Width | [mm] | 3080 | 3016 |

| Height | [mm] | 3060 | 2240 |

| Weight | [t] | 18 | 22 |

| *Approximate values. The exact parameters are specified in the machine’s installation plan | |||

| Maximum speeds | |

|---|---|

| Max. cutting speed | 100 m/min |

| Parallel to the X, Y axes* | 100 m/min |

| Simultaneously* | 140 m/min |

| *Top speed value is dependent on the machine’s working area | |

| Axis parameters | |

|---|---|

| Repetitiveness +/- | 0,03 mm |

| Cutting precision +/-* | 0,1 mm |

| Max. acceleration** | 20 m/s2 |

| Min. programmable leap | 0,001 mm |

|

*In accordance with PN-EN ISO 9013 norms **Top speed value is dependent on the machine’s working area |

|

| Available laser source | […] | 1kW | 2kW | 3kW | 4kW | 6kW | 8kW | 10kW |

|---|---|---|---|---|---|---|---|---|

| Mild steel | [mm] | 10 | 16 | 20 | 20 | 30* | 40* | 50* |

| Stainless steel | [mm] | 4 | 10 | 15 | 20 | 30* | 40* | 50* |

| Aluminium | [mm] | 2 | 6 | 12 | 15 | 30* | 35* | 40* |

| Brass | [mm] | 2 | 4 | 6 | 8 | 12 | 15 | 20 |

| Copper | [mm] | 1,5 | 4 | 6 | 6 | 10 | 15 | 20 |

|

Maximum thicknesses of the materials to be processed. The values that are achieved depend on the quality of the material being processed, the quality of the cutting gases, the quality of the service and the NC program and the condition of the wearing parts *Heavy duty (HD) laser cutter version with CatLine option |

||||||||

| Control | Beckhoff TwinCAT CNC |

| Compressed air pressure | [bar] | 6 |

| Nitrogen pressure | [bar] | 25-30 |

| Oxygen pressure | [bar] | 8-10 |

| Laser type | IPG fiber laser | |

| Available laser sources | [kW] | 1-10 |

| Wavelength | [µm] | 1,07 |

| Beam quality | mm x mrad | 3,4-4,0 |

| Frequency | [kHz] | 5 |